Cool storage monitoring

Monitoring the cooled storage of adhesives and electrolytes.

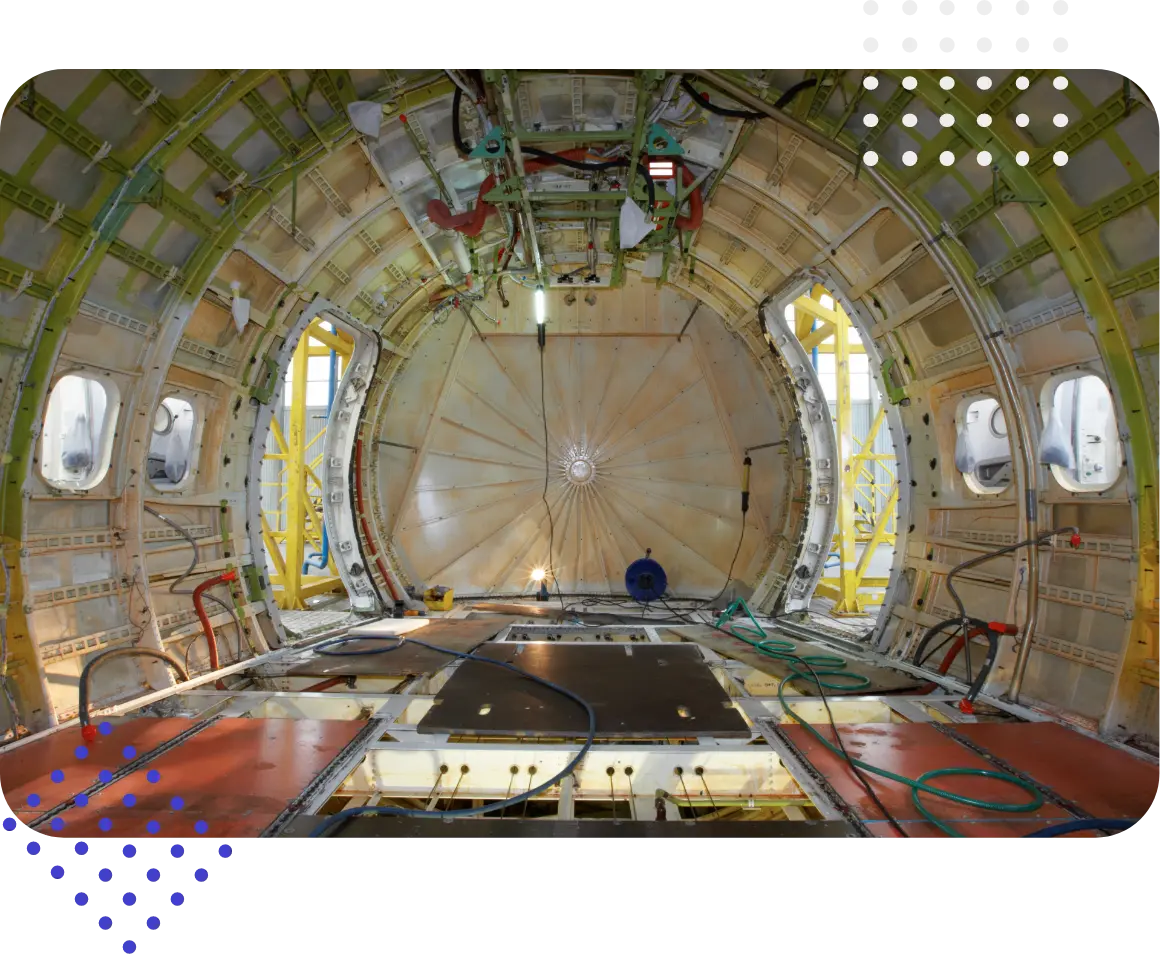

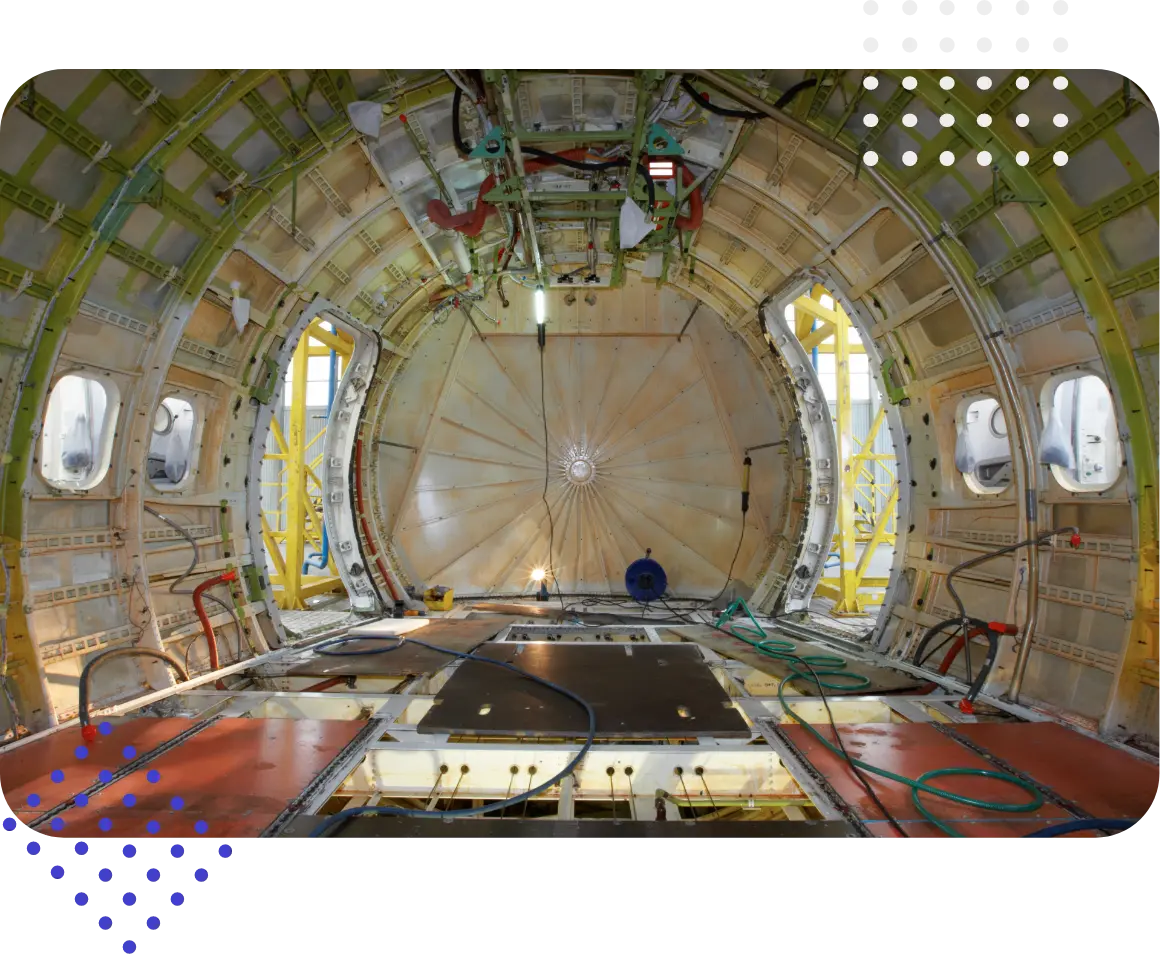

Aviation and automotive industry

In aviation, cooled storage of many adhesives is necessary to ensure their shelf life and to keep their chemical properties stable. Also in the manufacture of electric cars, electrolytes for lithium-ion batteries must be kept chilled to ensure their chemical stability and safety in handling.

Aviation industry

In the aviation industry, adhesives play a central role – whether in bonding components, sealing, or vibration damping. Many of these adhesives are chemically highly sensitive and must be stored under precise temperature conditions to maintain their functionality.

Why cooled storage is indispensable in aviation:

- Ensuring the longevity of temperature-sensitive adhesives and their material quality

- Ensuring consistent chemical properties for maximum bonding strength

- Avoiding curing or quality loss due to temperature fluctuations

Risks without controlled storage:

- Failure of safety-critical components due to adhesive failure

- High consequential costs from repairs and downtime

- Loss of quality in manufacturing and repairs

- Safety gaps due to human error (e.g., doors left open, plugs pulled)

Automotive industry

The automotive industry – particularly in the field of electromobility – increasingly relies on the precise storage of sensitive materials. A typical example is electrolytes for lithium-ion batteries, which must be stored under defined cooling conditions to ensure their chemical stability.

Advantages of refrigerated storage in the automotive industry:

- Ensuring the chemical stability of electrolytes for high-performance batteries

- Preventing material changes that can affect performance and safety

- Increased protection against thermal decomposition or ignition of the substances

Consequences of inadequate cooling:

- Potentially hazardous reactions from unstable chemicals

- Product liability risks and recalls

- Production downtime due to defective or contaminated materials

- Increased risk of fires or explosions in manufacturing

- High costs due to scrap and safety incidents

Temperature-controlled adhesive storage in aviation

DÜPERTHAL connect Monitoring in use at a leading aviation company