Battery storage monitoring

BATTERY line with 24/7 monitoring and a configurable alert system.

For users of lithium-ion batteries

Although lithium-ion batteries are very safe during normal operation, a risk arises when the batteries react thermally. Accordingly, preventive measures for the early detection of incidents are important components for ensuring safe workplaces and valuable inventory.

BATTERY station XL, with double-tested fire protection for over 90 minutes (explosive combustion of the batteries in the interior), tested backdraft protection, extinguishing-agent-free fire containment and a sensor-monitored warning system, offers the appropriate solution for:

Application examples

- Battery-powered tools

- E-bike batteries

- Lithium-ion batteries from scanners

Battery-powered tools

In many workshops, production facilities and craft businesses, battery-powered tools are part of everyday work. However, after work or on weekends, the batteries are often stored unprotected on shelves or workbenches — this poses a potential fire hazard. Defective or damaged batteries can react thermally and, in the worst case, cause a fire that can endanger not only the tools themselves but also buildings and valuable materials.

Recommended solution

A safe solution is the BATTERY station XL, which offers double-tested fire protection for over 90 minutes and is equipped with an integrated smoke detector, temperature monitoring, and a local and/or remote alarm system.

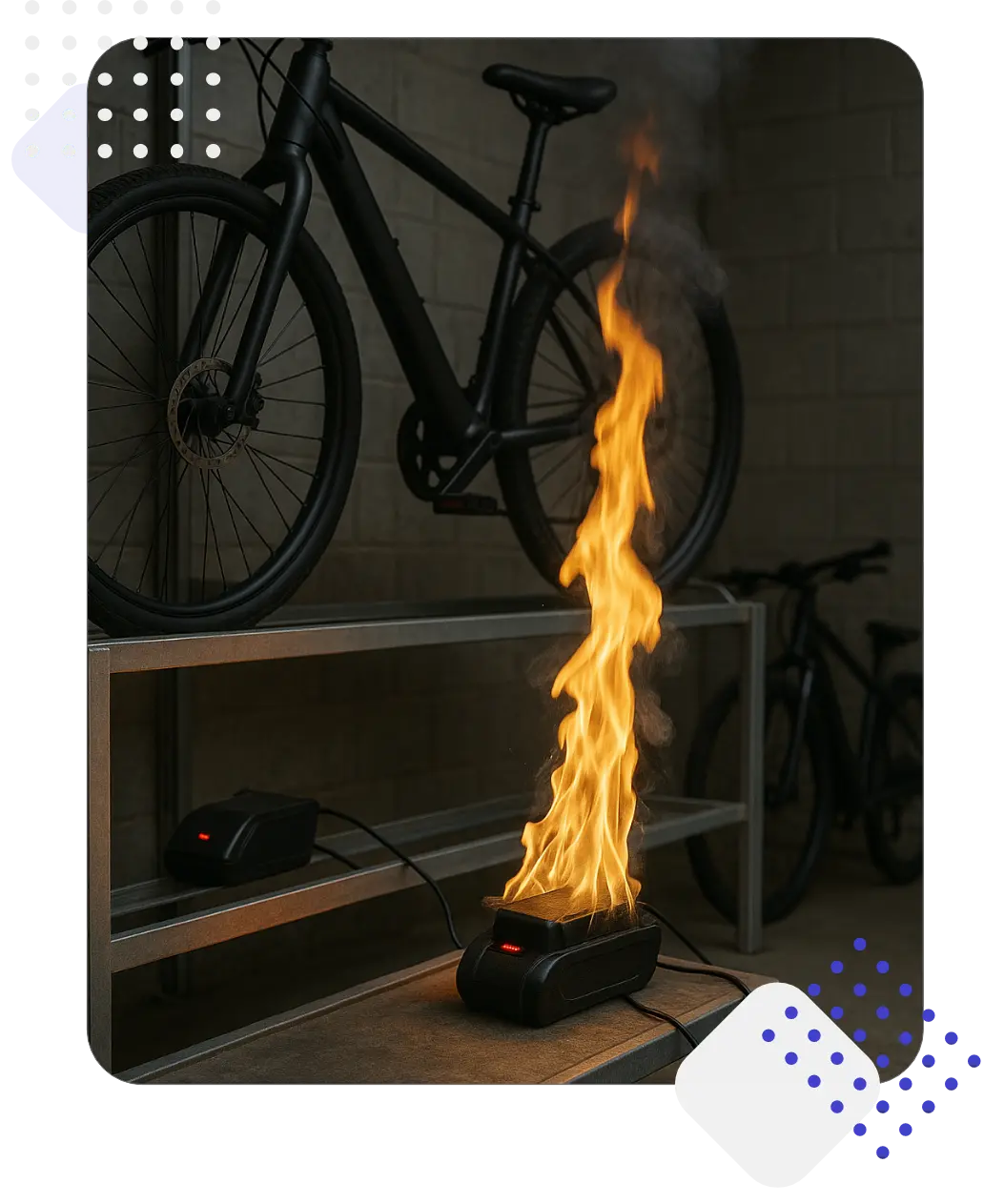

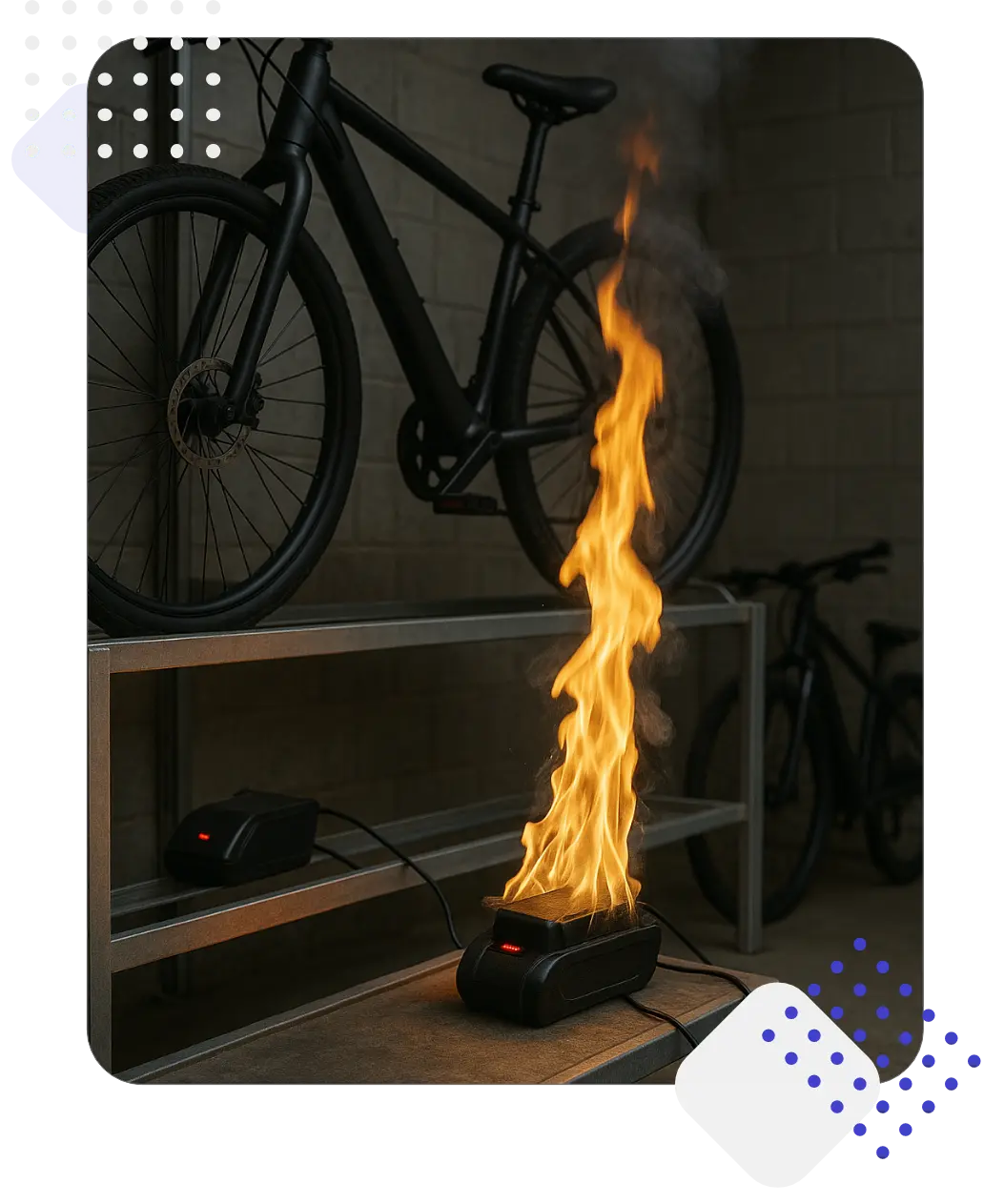

E-bike batteries

More and more employees in offices and universities are using e-bikes as an environmentally friendly means of transport. The batteries of these bicycles are often charged and stored in the bike cellar or in storage rooms. Especially during charging, dangerous fires can occur due to defective or reacting batteries, which can spread uncontrollably.

Recommended solution

The BATTERY station XL, with double-tested fire protection for over 90 minutes and with lockable compartments, temperature monitoring and remote alarm, provides safe and controlled storage of the batteries and thus minimizes the risk.

Lithium-ion batteries of scanners

In logistics centers and large warehouses, handheld scanners are indispensable for efficient goods capture. However, their lithium-ion batteries pose a fire risk not to be underestimated in the event of a malfunction. Since large quantities of easily flammable materials are often stored in warehouses, a battery fire can quickly develop into an uncontrollable hazardous situation.

Recommended solution proposal

The BATTERY station XL offers a secure solution for storing and charging these batteries. With double-tested fire protection of over 90 minutes and with a smoke detector, temperature control as well as a local and/or remote warning system, the risk of a spreading fire is significantly reduced and people, buildings and valuable goods are protected.

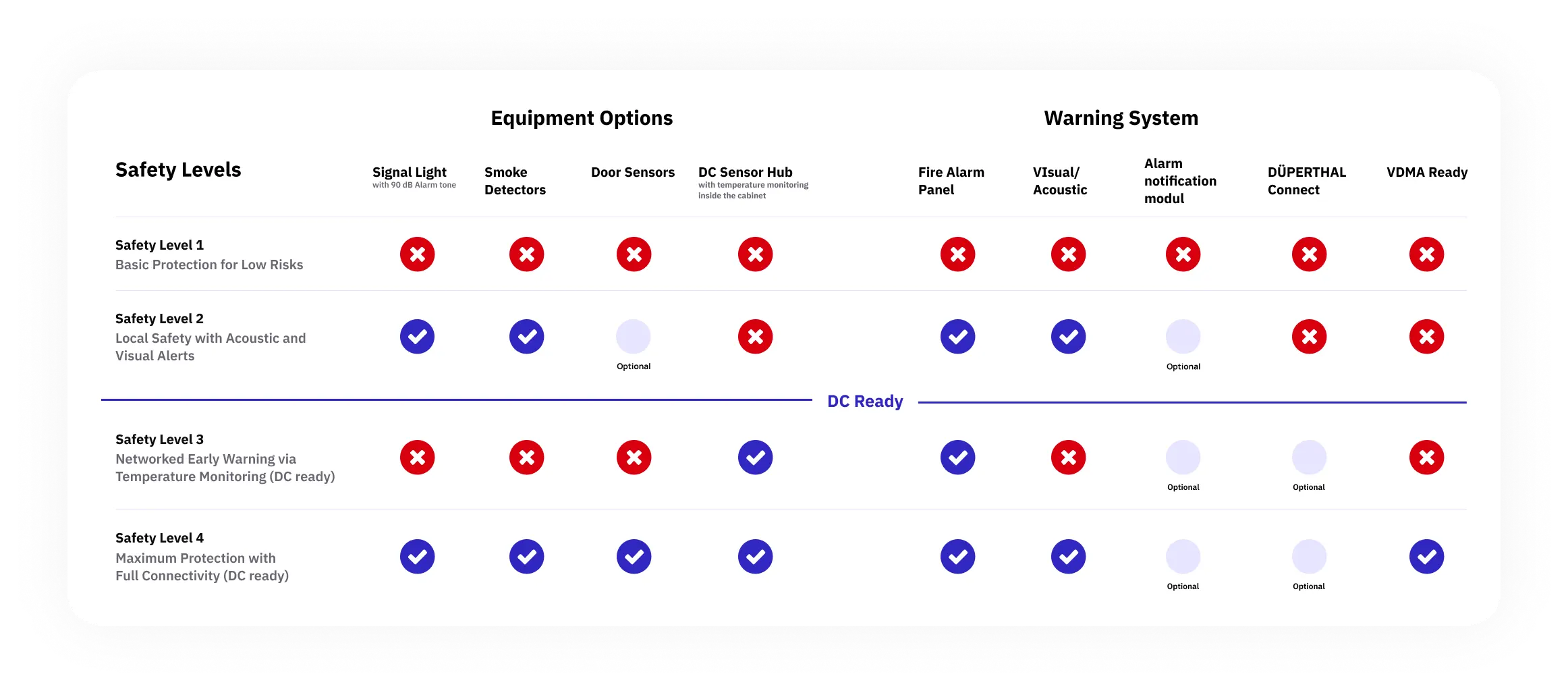

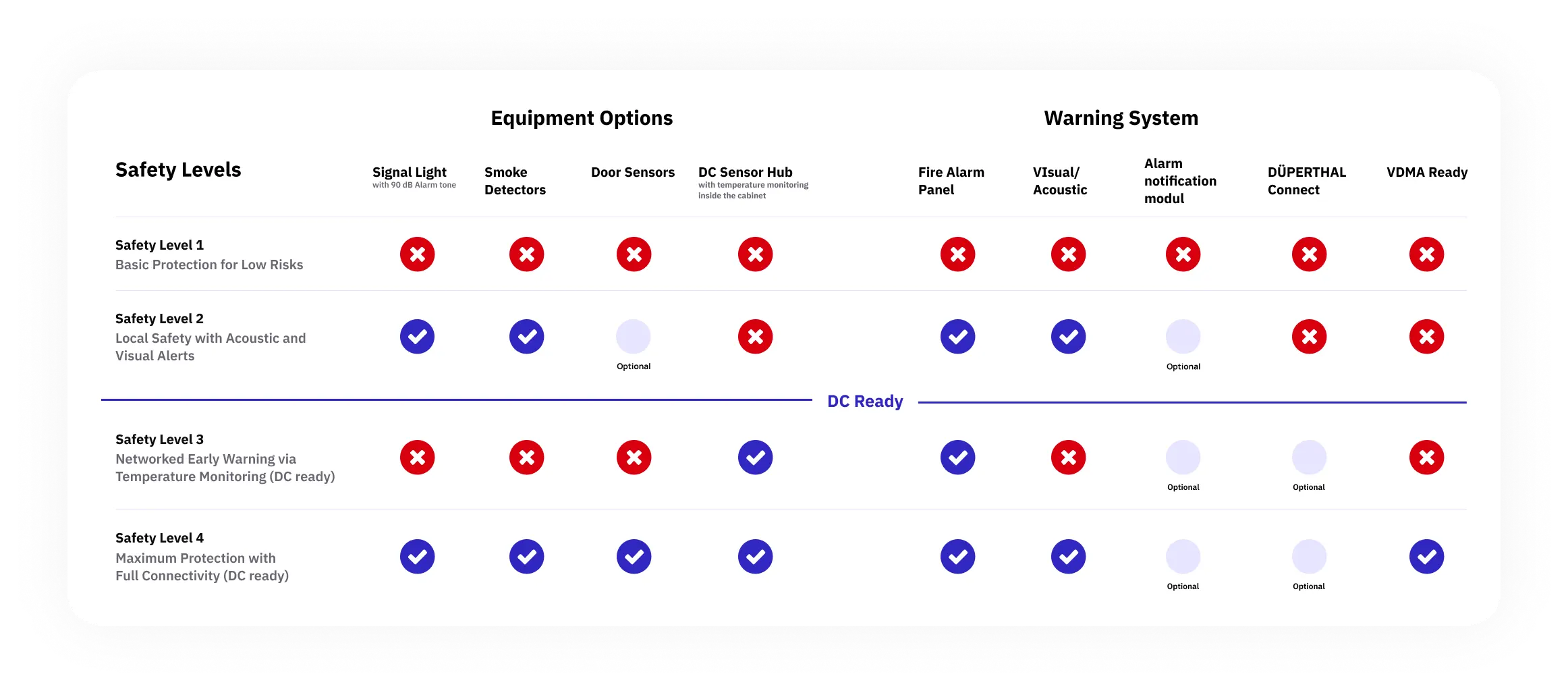

Alarm and warning systems – safety concepts

Flexible safety concepts enable the use of sensor-monitored safety cabinets – individually tailored to the requirements of each facility to ensure the fastest possible notification of hazardous situations.

Local alarm system

- Signal light and an audible signal on the safety cabinet - immediate visual and acoustic warning directly at the cabinet.

- Potential-free contact - by connecting the fire alarm system (BMA) on site to the potential-free contact, timely evacuation and fire-fighting are possible in the event of a fire.

Remote alarming via the DÜPERTHAL Connect (DC) software

- Cloud-based monitoring - real-time alarm notifications via email and SMS.

- Remote access - enables continuous monitoring and rapid response from any location.

DÜPERTHAL Safety concept at a glance

DÜPERTHAL has developed a modular safety concept for the storage and charging of lithium-ion batteries based on many years of experience and normative requirements.

It includes four safety levels to precisely map different hazard scenarios, from simple to highly sensitive applications. The levels combine passive protective mechanisms with active warning and monitoring solutions, integrated locally or digitally.

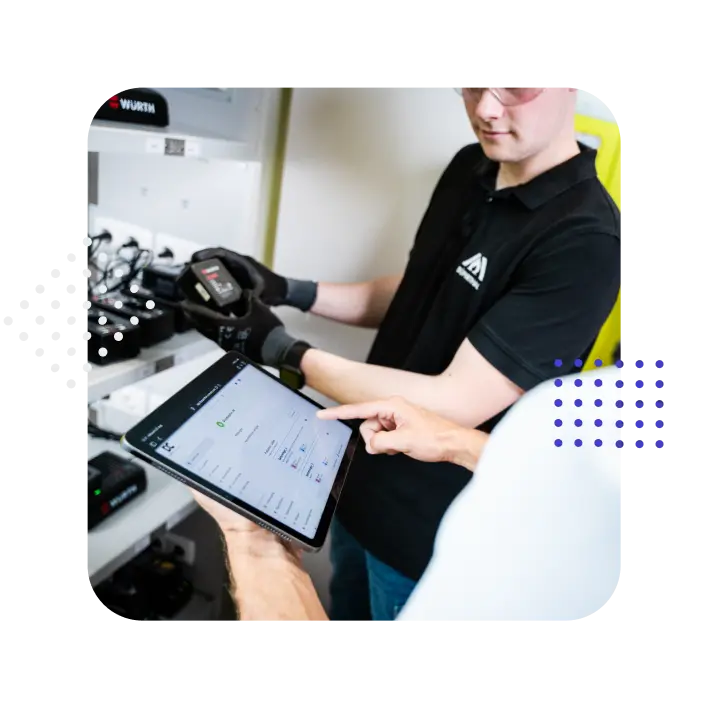

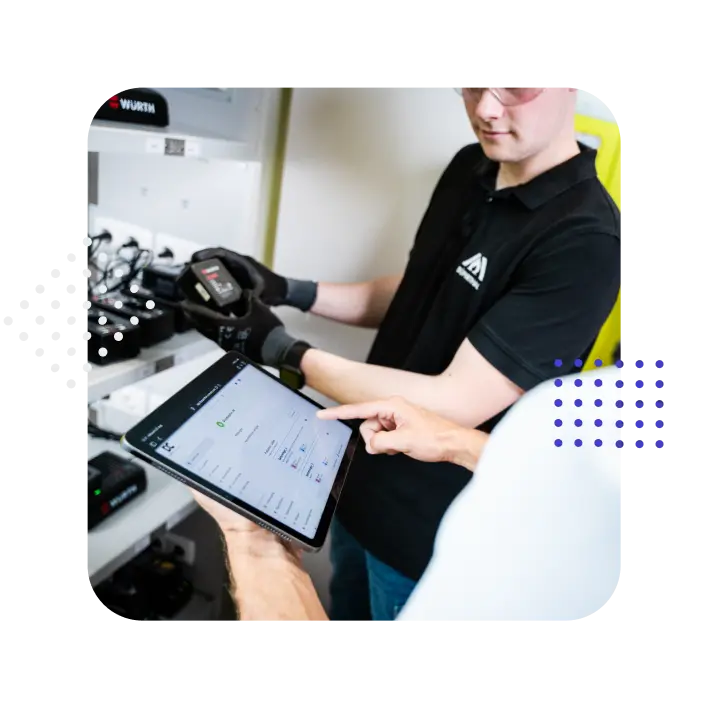

Battery-powered tools in a production facility

DÜPERTHAL connect monitoring is in use at DÜPERTHAL production facilities.